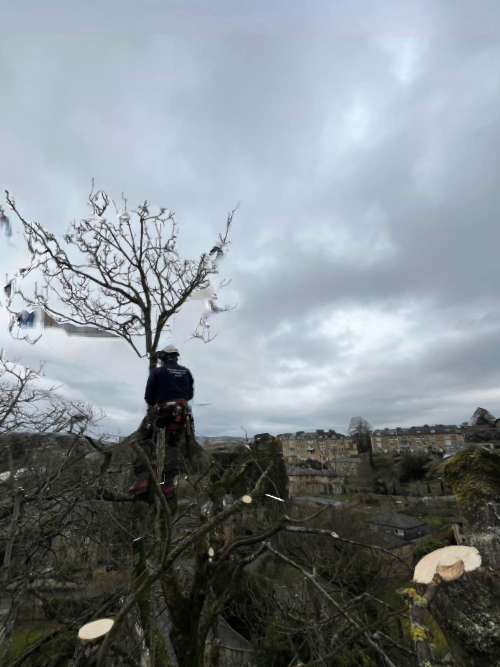

Felix undertaking some aerial rigging this week

Category: Tree Surgery

Deadwood removal and reductions in Hampshire April 2025

Deadwood removal and reductions in Hampshire 9th April 2025

Both MEWP teams out in Hampshire this week, undertaking some deadwood removal along with some small reductions over access routes

Great job by all in the sunshine.

Check out our MEWP information page here (also known as Cherry Pickers)

Tree Reduction overlooking the City of Bath

Here, Alex is undertaking a reduction to a mature veteran beech tree overlooking the City of Bath. This follows approval for the work to a TPO-protected tree.

The tree was 26m which we reduced to 22m. All done by ‘hand’ as there was no access for any machines.

Even our new company workwear is visible!

Street Pollarding

Mark pollarding willow trees along a watercourse

Here, Mark is pollarding willow trees along a watercourse, all made safe and easy with the Vosch grapple saw.

Pollarding is the process of cutting all limbs of the tree back to the main stem to reduce the weight and likelihood of the main stem splitting and failing. This can only be done on certain species of tree that will regenerate afterwards.

Check out all our tree services here and tree survey work here

And below is the link for more info on the Vosch if you’d like it.

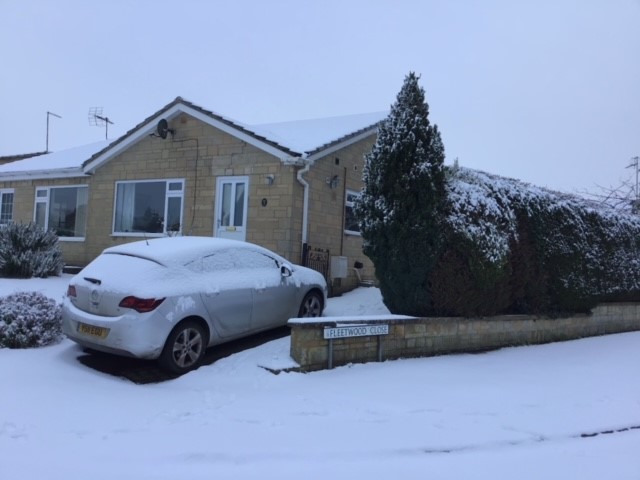

Removal of large conifer hedge, replacing with Close Board fencing on Duraposts.

We removed a large conifer hedge including the stumps near Corsham as it was impacting on the wall . The hedge was then replaced with a 6ft close board fence on Duraposts and were delighted to receive this feedback from Jo.

“ Just to say I went back home at lunchtime today to discover everything was finished. Your team have done a fabulous job and all of your workers have been really great. I’m really pleased with the result, thank you. They’ve all been cheerful, polite, friendly and have tidied up everything beautifully. Please can you pass on my appreciation to them all as well, and I will definitely be recommending you guys. If only I could employ you to fix the house!

All the best and thanks again. Jo”

For details of the many types of fencing we offer, including Duraposts, please see here.

Ash clearance checking for bat roosts

Last one for this week.

As part of an ash clearance, we had surveyed all the trees in the woodland last year.

Those with potential bat habitat were recorded and numbered. These were then checked again from a MEWP with an ecologist prior to felling.

Following that, 4 trees of the 143 trees surveyed, were found to have bats within them so were left untouched.

Dismantle of a multi stem beech tree at Edington which was in decline

We recently felled a multi-stem 20m high beech tree opposite The Three Daggers pub in Edington .The tree was right by the road and was showing signs of dying back. Its position made it unsafe to remain. We were pleased to receive this testimonial from our client:

“Your guys have just felled a large beech tree adjacent to our drive. I wanted to let you know what a good job they did.

The notice said the road would be closed for 2 days but they completed the job in less than 6 hours; very impressive kit, very efficient and helpful. All cleared up tidily, and they left me a gift of logs for firewood.

I was very impressed. Richard”